REPAIR AND MAINTENANCE

Allround Storage Solutions can offer customers a comprehensive repair and maintenance service on most equipment. We use a 3rd party contractor that are specialists in their field and very well respected throughout the industry - Roll Cage Maintenance.

Their service is Nationwide so it doesn't matter where in the UK you are as they can still reach you. The mobile engineers will arrive on-site at a time that is convenient to you, fully equipped to carry out the repairs with all the necessary equipment and permits. All risk assessments are carried out beforehand. Detailed reports will be available after the engineers have finished which will provide you with all the management information you need.

All damaged equipment is fully serviced, so if a repair is obvious they do not simply fix that repair but completely overhaul the equipment to ensure there are no other faults. All welds are then coated with a rust-inhibiting paint. The aim is simple - to provide you with excellent service at competitive rates. Reputation means everything to them so they set their maintenance service levels and customer service levels very high.

As distribution systems evolve and warehouse processes change, equipment can often become outdated or even obsolete. Because we understand that these processes take place sometimes the more cost effective option is to modify existing equipment rather than buy new. This can be a result of new HSE directives and updated internal procedures or vehicle fleet changes. The modification can be as simple as retro-fitting a marker board or nameplate to more complex design changes. Either way we are fully equipped to carry out these modifications, usually at your premises too so you don't lose control of your assets.

Should your fleet already be fitted with bar codes then the damaged equipment can be manually scanned during the maintenance proc ess. The engineers can then catalogue the nature of the repair work carried to each individual piece of equipment, allowing you the benefit of building up a database of historical information. With our help, this information can then be used to find out the most common failings and where the most common damage is received. With this knowledge we can advise you accordingly and look at the working practices within the Distribution Cente or Warehouse to identify why this damage is occurring, and what measures we can put in place to restrict it from happening.

Are you thinking about the possibility of starting an asset tracking system?

Do you like the idea of this system?

Are you interested in a low cost initial trial?

Did you know that the typical annual shrinkage rate for RTI's is between 5% and 8%

Roll Cage Maintenance can help you at the ground level by initially fitting bar codes or RFID tags to some of your equipment or even just the repaired equipment to start with. This means that data can immediately start being collected, and with a very cost effective tracking solution to begin with which incorporates the use of a few hand-held scanners, the equipment cycle can immediately begin to be monitored. The data collected might show that your equipment is not being returned to you as it should be, or indeed not being retuned at all which can have a very damaging impact on the Distribution System.

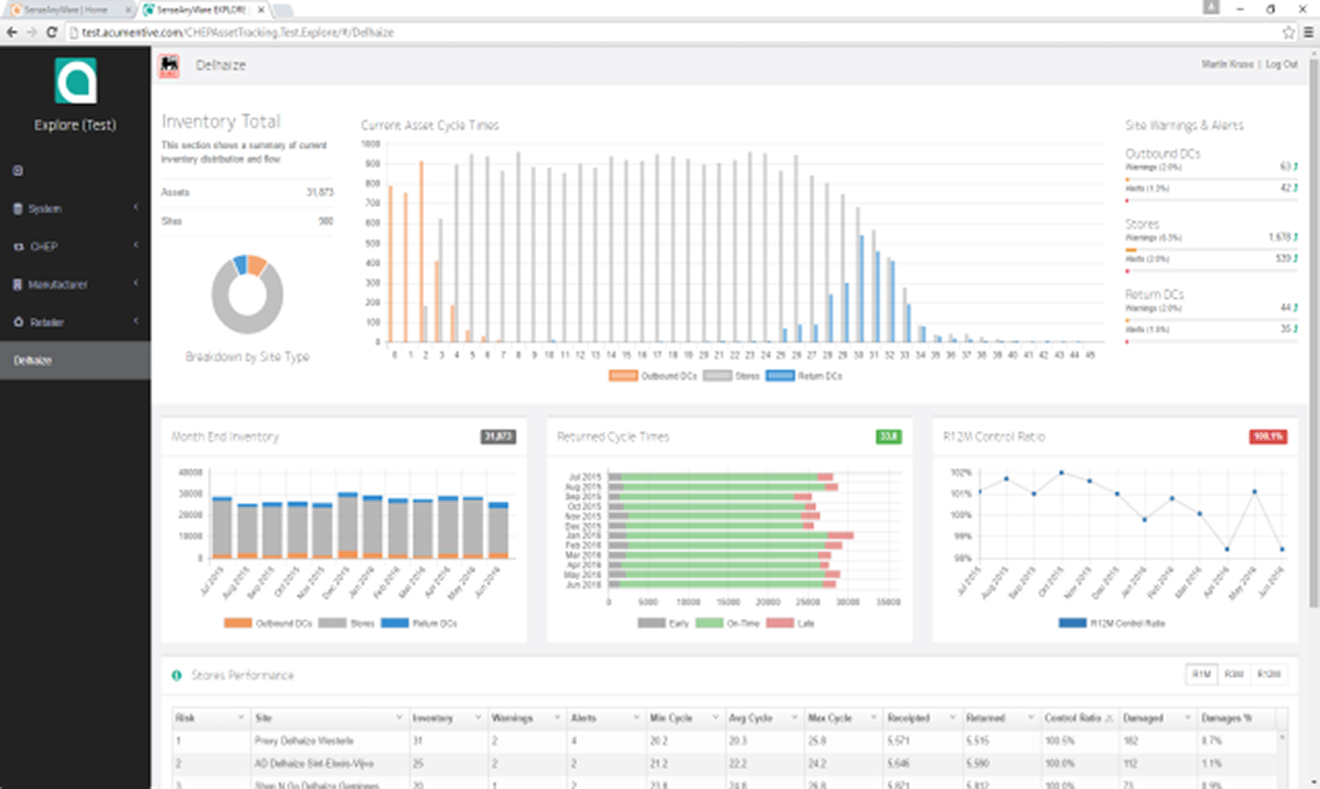

If the data is highlighting this then we can investigate the need to expand the trial further and perhaps monitor specific journeys or cycles to identify where and why these losses are occurring. Again this can be achieved with a relatively low cost hardware expense. Once the trial is complete and all the data has been analysed there could be a requirement to bar code or tag all the equipment and implement a full auto-ID system which will automatically track each asset in real time. This will depend on what the data shows and the cost of an Auto-ID system versus your return on investment, although there are differing levels of hardware and investment possibilities available for you to choose from.