RTLS

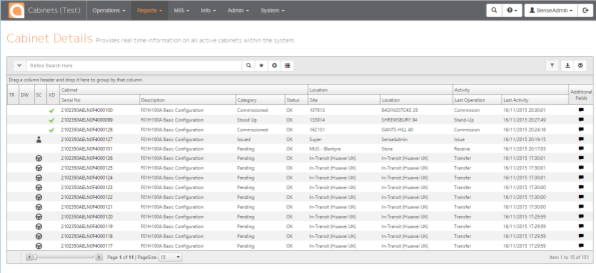

A Real Time Location System (RTLS) is a more complex integrated technology combining the best of RFID, Bluetooth and WiFi. Sometimes the technology can also use optical and infrared communication. Relying on a series of fixed readers strategically placed in the warehouse or workplace, our system can locate and track assets or people that have tags fixed. The battery-powered tags emit a continuous signal that is monitored by the readers, and by way of a triangulation algorithm our system can pin-point the asset or person to within one metre if necessary.

With a few more strategically placed readers the height from the floor can also be calculated, so the system would also know the height of an asset. Couple this with a reader on the fork lift or high-bay order picker that would read the label on the asset being stored away you have a completed auto-ID loop. At the press of a button, and in real time, our software will show you a complete stock and inventory report using a virtual computerised warehouse site map and overlay. You will know exactly what is in the warehouse and maybe more importantly exactly where it is in the racking or warehouse.

No more downtime searching for lost or misplaced pallets!

It doesn’t stop there either, with a reader and antennae on the MHE you can very simply access information such as which particular piece of MHE placed the pallet in the racking, what time this was done, who was the operator etc. With omnidirectional antennae, our software can also allow for inbound/outbound racking placement so you have full control over stock management.

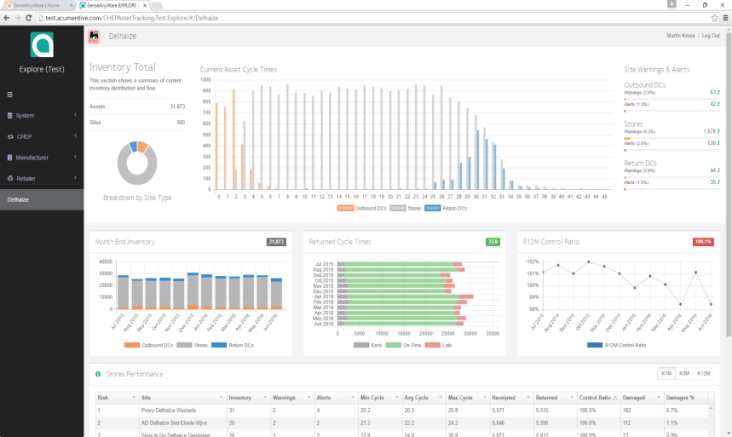

The system not only pin-points an asset or person at any given time, it can also track and record the historical movement. This can provide invaluable data and management information for you to consider because with our software this information can be converted to insightful and detailed reports. These reports will highlight the possible areas where the warehouse is not operating to maximum efficiency levels and, if this is the case, can save your company money off its bottom line. A simple time and motion study will show what you should be achieving v factual data of what is actually being achieved – no more guess work! Our systems can identify any root problems pertaining to this and we can help you address these concerns.

Health & Safety is also a very important factor of any business, and this is also what an RTLS system can highlight. Accident hot-spots can be identified, accountability recorded and problems addressed. MHE re-routing can be planned for, within the constraints of a fully-efficient operating warehouse, and operators made aware of the documented hazards and H&S procedures can be revised accordingly